- Home

- Enviorment-Social-Governance

Environment

Protect our Planet Program

With the aim to drive focused execution efforts under our sustainability agenda, we launched our Protect Our Plant (“POP”) Program in FY 2022-23. The POP team comprises cross-functional representatives from key functions within the organisation, ensuring representation from all relevant stakeholders. This team is chaired by 3 (three) members of our Executive Committee, who conduct monthly reviews to track the progress of the POP agenda. Additionally, the Managing Director reviews it on a quarterly basis. The on-ground implementation of the program is executed by cross-functional teams that report directly to the Executive Committee.

POP provides us with a strong governance system to evaluate projects. We prioritise key themes identified through comprehensive materiality assessments, allowing us to align our sustainability initiatives with the critical environmental and social issues that are relevant to our business. This empowers us to address and prioritise the most significant aspects of sustainability in our decision-making processes.

The themes are as follows:

Decarbonisation

Water management

Circular economy

Biodiversity

Product social responsibility

Air emissions

As part of our program, we have engaged a third-party agency to provide independent limited assurance on select environmental performance indicator disclosed in this report as per GRI Standards. Additionally, we have established environmental targets for the period spanning from FY 2024 to 2026. The details of these targets are as follows:

Decarbonisation

As India’s fifth-largest cement group in terms of capacity, we see ourselves playing an important role in the industry’s efforts to mitigate climate change in alignment with the country’s Nationally Determined Contribution (“NDC”).

During the cement manufacturing process, CO2 emissions are released due to burning of fossil fuels and burning of raw mix which contains CaCO3 as main constituent. At Nuvoco, we have identified levers to reduce our CO2 emissions and have long-term decarbonisation strategy in place to meet the country’s NDC.

Our Target: 2% carbon emissions intensity reduction on a year-on-year basis

Cement

CO2 emissions (Scope 1) 445 Kg per tonne of cementitious materials by 2025

RMX

2.63 KgCO2/ m3 concrete produced (Scope 1 + Scope 2) by 2025

| Emissions | FY 2022-23 | FY 2021-22 |

|---|---|---|

| Cement (KgCO2/ tonne of cementitious products) - (Scope 1 | 462 | 478 |

| Ready Mix (Scope 1 + Scope 2) - KgCO2/ m3 Concrete produced | 2.89 | 2.79 |

Our decarbonisation strategy comprises the following aspects:

Green and alternate energy: We have implemented facilities that enable us to harness renewable sources of energy, as part of our efforts to gradually reduce our reliance on the grid. Furthermore, we have clear plans in place to enhance capacity in the near future.

We have ensured functional and efficient Waste heat recovery systems (“WHRS”) at all our integrated plants. Plans are underway to further enhance this capacity through optimisation measures. In addition, we plan to gradually transition our grinding units to use more Green Energy.

Combined installed capacity of our WHRS systems

Of our energy requirements fulfilled through cleaner sources

Solar power: We have installed captive solar power plants at 2 (two) of our cement plants, viz. Chittor Cement Plant and Haryana Cement Plant (Bhiwani). Currently, our focus is on expanding this capacity to over 5 MWp by installing solar panels at 2 (two) additional plants, viz. Odhisa Cement Plant (Jajpur) and Bihar Cement Plant (Bhabua).

Our Target Solar Power capacity

by FY 2023-24

by 2025

Renewable energy

Existing solar power plant capacity

Alternate Fuel and Raw Materials (“AFR”): Using alternate fuels is a crucial step towards decarbonisation and a specific opportunity for our industry to help reduce waste while also limiting our spends on other sources of energy. Our alternate fuel mix comprises solid waste, liquid solvent, biomass, refused derived fuels from municipal solid wastes and other substances. Our performance in this regard has consistently improved. Our AFR at 9% in FY 2022-23 has doubled from 4.5% clocked in FY 2021-22.

We are making efforts to increase the AFR feeding capacity at our plant in Nimbol, Rajasthan, and Risda, Chhattisgarh.

AFR target for FY 2023-24

Sustainable Product Mix: We are increasing our use of blended cement in several of our premium products to substitute Ordinary Portland Cement. We have consistently maintained an average cement to clinker (C/K) ratio of 1.8.

We are working to further increase the share of Portland Composite Cement (“PCC”) and Portland Slag Cement (“PSC”) which are high in cementitious additions.

| Cement to Clinker ratio | |

|---|---|

1.82FY 2022-23 |

1.80FY 2021-22 |

Water management

Water conservation is an integral part of our sustainability program, and we have developed a long-term strategy for preserving this precious resource. Through our CSR programs, we are taking several steps to conserve water by harvesting rainwater within our premises and surrounding areas. Nuvoco considers water management as one of the key assessments under materiality topics. As a natural resource, water needs to be protected. As a result, we have taken initiatives to reduce our freshwater consumption through a well-structured ‘5R’ approach.

Our strategy for water conservation, reduction and recycling aligns to “5R” approach. This includes:

- Water-efficient technologies are being deployed at our cement plants, captive power plants, and waste heat recovery systems to minimise water consumption.

- Maintaining Zero Water Discharge at all sites

- Recycling of waste treated water

- Ground water recharge

- Rainwater harvesting within and outside fences

Our targets in water management

Committed to reducing our water use by 5% on a Y-o-Y basis

Becoming Water Positive – 2.0x by 2025

Reducing our Specific Freshwater Consumption (Overall) by 2025 to:

- 52 L/tonne of Cementitious products (Process)

- 0.23KL/m3 of concrete produced

Our performance in water management during FY 2022-23

Water Positive Index

Of sewage treated wastewater into sprinkling, gardening and other processes

Specific freshwater consumption (L/tonne of cementitious materials) in FY 2022-23

concrete produced in FY 2022-23

Circularity

The main objective of a circular economy is to decouple economic growth from the consumption of natural resources by reducing and recirculating them. Nuvoco fully supports this path to a ‘waste not, want not’ lifestyle. The concept involves extending the lifecycle of products and reusing them in some way at the end of their lifecycle.

Our contributions to circular economy are as follows:

- Through our responsible use of alternative fuel and raw materials (“AFR”), we actively participate in reducing waste generated by other industries by repurposing it for productive use

- Our Waste Heat Recovery Systems (“WHRS”) enable us to significantly increase our utilisation of green energy, accounting for approximately 20% of our total thermal energy requirements.

- We maintain a Cement Clinker ratio of 1.8, effectively minimising waste materials such as fly ash from Thermal Power Plants and slag from steel industries.

- Our Ready-Mix Concrete (“RMX”) plants rely on the availability of construction and demolition (“C&D”) waste. By incorporating recycled aggregates from C&D waste, we have successfully replaced around 10% of crushed sand, thereby conserving natural resources.

- To further promote sustainability, we utilise fly ash and slag, by-products from Power Plants and the Steel industry, as valuable input materials in the production Pozzolanic Cements and Concretes.

Water Positive Index

Alternate material used in total raw materials consumed to produce concrete

Alternate materials used in total raw materials consumed to produce cement

Biodiversity protection

Our mining operations involve working close to natural resource sources. As a result, we are becoming increasingly aware of the need to protect biodiversity, as well as the challenges caused by climate change.

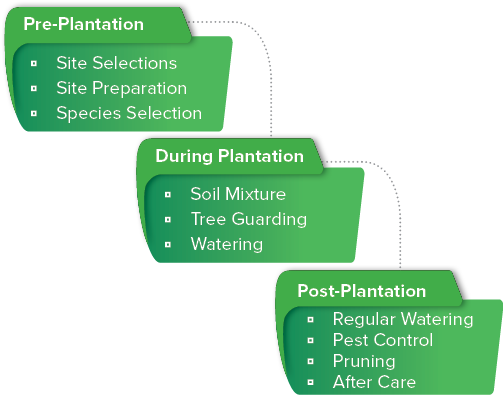

We have developed a Standard Operating Procedure at Nuvoco that focuses on the planting of native species of plants. The presence of native species contributes to the maintenance of the ecosystem by maintaining the flora and fauna.

Prior to the planting of these saplings, we select the sites and prepare the sites carefully to ensure the highest chances of success. We also select the plant species that are most suited to the geographical and climactic conditions at the site.

We choose the right seasonal time for planting the saplings along with ensuring the soil mixture that is most conducive to growth. We also undertake regular watering, care, and plan guarding measures so ensure the saplings are not infested by pests or eaten up by animals. After the plantation, we ensure regular watering and pest control as well as seasonal pruning and regular use of manure. It helps to nurture our plants and grow well into trees that are able to support life.

During the fiscal year, we have conducted an in house study to estimate Carbon Sequestration through the planted trees till now, at Arasmeta Cement Plant. We are targeting to conduct similar studies at our other plants during the FY 2023-24. These studies help us to understand our commitment toward carbon neutrality program and to further enhance native trees plantation, to estimate carbon sequestration potential at Novoco through native tree plantation drive.

Saplings of native species

Survival rate 9 months after plantation

Our operations at Nuvoco have been designed to minimise the risk of environmental damage to biodiversity surrounding our manufacturing facilities. At all of our mining operations, we have implemented Wildlife Conservation (“WLC”) Plans in accordance with the requirements outlined in our Environmental Clearance. We are achieving the targets specified WLC for wildlife conservation.

Product Social Responsibility

We firmly believe in the power of our innovative capabilities to drive further efforts towards climate change mitigation at the consumer-level. Our product development strategy is embedded with an approach to product social responsibility which makes the use of our products not only safe but also environmentally responsible.

When such products are adopted at scale, it creates a multiplier effect towards green efforts. Moreover, our product social responsibility encompasses our efforts to transport and deliver our products in an environmentally responsible manner, ensuring reach to the end-consumer.

- We have pioneered green products with introduction of cement products like Concreto, Duraguard and ECODURE concrete. Our Ecodure range of products has received the GreenPro Certification from the Indian Green Building Council (“IGBC”), part of the Confederation of Indian Industry (“CII”) at 5 (five) locations in FY 2022-23. This certification has been granted to our 6 (six) facilities, demonstrating our commitment to environmental sustainability.

- We are actively collaborating with agencies like National council for Cement and Building materials (“NCCBM”) on Limestone Calcine Clay Cement (“LC3”) which will further improve our C/K ratio.

- We are converting our fleet of vehicles to CNG & Electric Vehicles; we have also launched light-weight aluminium body trucks helping to indirectly reduce our carbon emissions.

Air emissions

- We regularly monitor our non-greenhouse gas (“GHG”) air emissions, which result from the burning of fuels in our cement manufacturing process and power generation at our captive power plants. The burning of fossil fuels is responsible for the release of Oxides of Sulphur (SOx), Oxides of Nitrogen (NOx), and Particulate Matter (PM). Therefore, we closely monitor these pollutants on a regular basis

- We track emissions as per the regulatory guidelines using the Continuous Emission Monitoring System (“CEMS”). We continuously monitor air quality fugitive emissions as per the regulatory guidelines. During the year under review, our stack and fugitive emissions were within the permissible limits set by the Pollution Control Boards.

| Stack Emissions (tonne/ tonne of Cementitious Products) | FY 2022-23 | FY 2021-22 |

|---|---|---|

| Oxides of Sulphur (SOx) | 0.07 | 0.11 |

| Oxides of Nitrogen (NOx) | 0.73 | 0.80 |

| Particulate Matter (PM) | 0.07 | 0.08 |

Environmental performance indicators as per Global Reporting Initiative Standards are subject to external assurance

| GRI Indicators | FY 2022-23 | FY 2021-22 | |

|---|---|---|---|

| ENVIRONMENT | |||

| 301-1 - Materials used by weight or volume | i. non-renewable materials used (Natural Materials - Raw meal including limestone, sand & aggregates) - tonnes | 2,39,39,237 | 2,43,15,155 |

| ii. reused materials (Flyash, Slag & chemical gypsum) - tonnes | 79,70,393 | 63,86,023 | |

| 301-2 - Recycled input materials used | Percentage of Recycled/ reused input materials used to manufacture the organisation's primary products and services | 24.98% | 20.80% |

| 302-1: Energy consumption within the organisation | Total fuel consumption within the organisation from non-renewable sources (GJ) - Includes alternate fuels other than biomass | 3,60,27,165 | 3,68,87,533 |

| Total fuel consumption within the organisation from renewable sources (GJ) | 4,10,436 | 689 | |

| Electricity consumption (GJ) - Grid | 25,01,003 | 20,54,927 | |

| Electricity consumption (GJ) - (WHRS & Solar) | 9,10,704 | 8,85,445 | |

| Total energy consumption (GJ) | 3,98,49,308 | 3,98,28,594 | |

| 302-3: Energy intensity | Energy intensity ratio for the organisation (GJ/ tonne of Cementitious materials) | 2.11 | 2.17 |

| *Specific Heat Consumption (Kcal/ Kg Clinker) | 712 | 716 | |

| 303-3: Water withdrawal | Total water withdrawal from all areas (Mega Liters) | 3,307.2 | 3,461.3 |

| Total water withdrawal from all areas with water stress# (Mega Liters) | 667.1 | 547.2 | |

| 303-4: Water discharge | Total water discharge to all areas in megaliters, and a breakdown of this total by destination | Implements ZLD at all sites | |

| 303-5: Water consumption | Total water consumption from all areas (Mega Liters) | 3,307.2 | 3,461.8 |

| Total water consumption from all areas with water stress# (Mega Liters) | 667.1 | 547.2 | |

| 305-1: Direct (scope 1) emissions | Direct (Scope 1) GHG emissions in metric tons of CO2 | 87,25,384 | 87,76,430 |

| 305-2: Indirect (scope 2) emissions | Indirect (Scope 2) GHG emissions in metric tons of CO2 | 4,93,773 | 4,95,271 |

| 305-4: GHG emissions intensity | GHG emissions intensity ratio for the organisation | 462.2 | 478 |

| 305-7: NOx, SOx, and other significant air emissions | SOx - tonnes | 1,324.6 | 1,511.5 |

| NOx- tonnes | 13,885.4 | 14,915.1 | |

| Particulate Matters - tonnes | 1,258.8 | 1,332.9 | |

| 306-2 - Management of significant waste-related impacts | Actions, including circularity measures, taken to prevent waste generation in the organisation’s own activities and upstream and downstream in its value chain, and to manage significant impacts from waste generated. | Please refer page 56 | |

| If the waste generated by the organisation in its own activities is managed by a third party, a description of the processes used to determine whether the third party manages the waste in line with contractual or legislative obligations. | |||

| The processes used to collect and monitor waste-related data. | |||

| 306-3: Waste generated | Total waste generated (tonnes) - (Plastic, ewaste, biomedical, batteries, Hazadous and Fly ash) | 4,84,746 | 5,08,007 |

| 306-4: Waste diverted from disposal | Waste recycled and reused (tonnes) | 4,84,375 | 5,86,181 |

| 306-5: Waste directed to disposal | Waste disposed (tonnes) | 1,119 | - |

*Note- Not a GRI disclosure.

#As per the Central Ground Water Authority (CGWA) list of notified area.

Social

For our communities

Nuvoco has a steadfast dedication to sustainable development, which is reflected in its core value of care. The Company’s CSR initiatives aim to foster socially sustainable programs related to health, education, livelihood, and environmental protection by collaborating with pertinent stakeholders. The goal of these initiatives is to establish self-sufficient communities by means of sustainable development efforts, where local communities can effectively participate and generate significant value.

Shikshit Bharat

Our initiatives under Shikshit Bharat are focused on providing access to new-age education and improving the quality of education by providing better infrastructure facilities like electricity, drinking water facilities, teaching aids, toilets and even, school boundary walls. We also organised specialised coaching sessions and competitions for children in a variety of disciplines and presented awards to the top-performing students. Apart from this, we are also supporting nearby government schools with installation of Smart Classes to enhance quality of education.

Swasth Bharat

Bringing good health and hygiene to as many people as we can is our primary objective under Swasth Bharat. Our focus is to provide access to primary health care, improved sanitation and safe drinking water to the communities and to address the needs of adolescent girls. We had conducted campaigns to spread awareness among adolescent females about ‘Menstrual Hygiene Management’ and also established a ‘Sanitary Napkin Pad Bank’. Additionally, we have conducted health checkup programs in schools and villages, reaching over 3,000 beneficiaries. We have adopted Anganwadis, in villages near our plant and upgraded them as model Anganwadis and also assisted them in improving their overall health service delivery in rural areas.

Saksham Bharat

Saksham Bharat is about giving opportunities to people by imparting new skills to the youth and women and enabling them to become self-reliant and improve overall quality of life. Under this theme, we have conducted skill development program for rural youths in association with specialised agencies. Post completion of their program, they are also assisted in securing placements as per skills gained by them. In last 2 years, we have trained more than 500 girls from rural areas out of which 280 have been engaged in meaningful employment or started their own inititatives. We are also working closely with more than 550 farmers in state of Bengal to promote sustainable agriculture techniques and also enhance their income by promoting agri allied activities as well.

An initiative to develop the Masonry Skill of the workers as per the National Skills Qualification Framework (“NSQF”), empower them and open new earning opportunities for them. This program consists of ~300 hours of training (theoretical and practical application) on subjects covering

brick masonry, plastering (interiors), putty (interiors), tile masonry (floors and walls), and PCC work. Currently, the programme is conducted in the states of Rajasthan and Chhattisgarh through our implementation partners. Around 100 youths benefited through this program in FY 2022-23.

Sangrahit Bharat

Natural resources are getting scarce with the increasing population, so it is essential to conserve them. Through this pillar, Nuvoco promotes use of renewable and clean energy, water harvesting and attempts to reduce carbon footprints by planting trees across all our sites. We also take efforts to reduce fossil fuel consumption and conserving water through initiatives like installing solar streetlights, solar plants, rainwater harvesting and pond deepening.

Sanrachit Bharat

Through this initiative, we have been working towards developing community infrastructure through the construction and repair of roads, refurbishment school buildings and build community centres along with boundary walls, improve drainage systems in villages and conduct tree plantations in communities and villages where we operate.

Governance

Key trainings conducted to raise levels of corporate governance

Through the year, we have placed a high priority on raising employee awareness regarding Nuvoco’s commitment to exceptional corporate governance. Toward this end, we conducted 26 workshops, each focused on fostering awareness of Nuvoco’s Code of Business Conduct and Preventing Sexual Harassment at Nuvoco. Our initiatives aimed to empower our workforce and reinforce the values and standards that define our organisation.

Covered under trainings for POSH and Code of Business Conduct

Response to stakeholder grievances During FY 2022-23, we have received 2,167 complaints in all from our key stakeholders, including our shareholders, employees, partners, and customers. 98% of the complaints have been addressed during the year.

As a responsible corporate citizen, we believe in open and transparent communication with each of our stakeholders. We facilitate our stakeholders with specific platforms to make their voices heard.